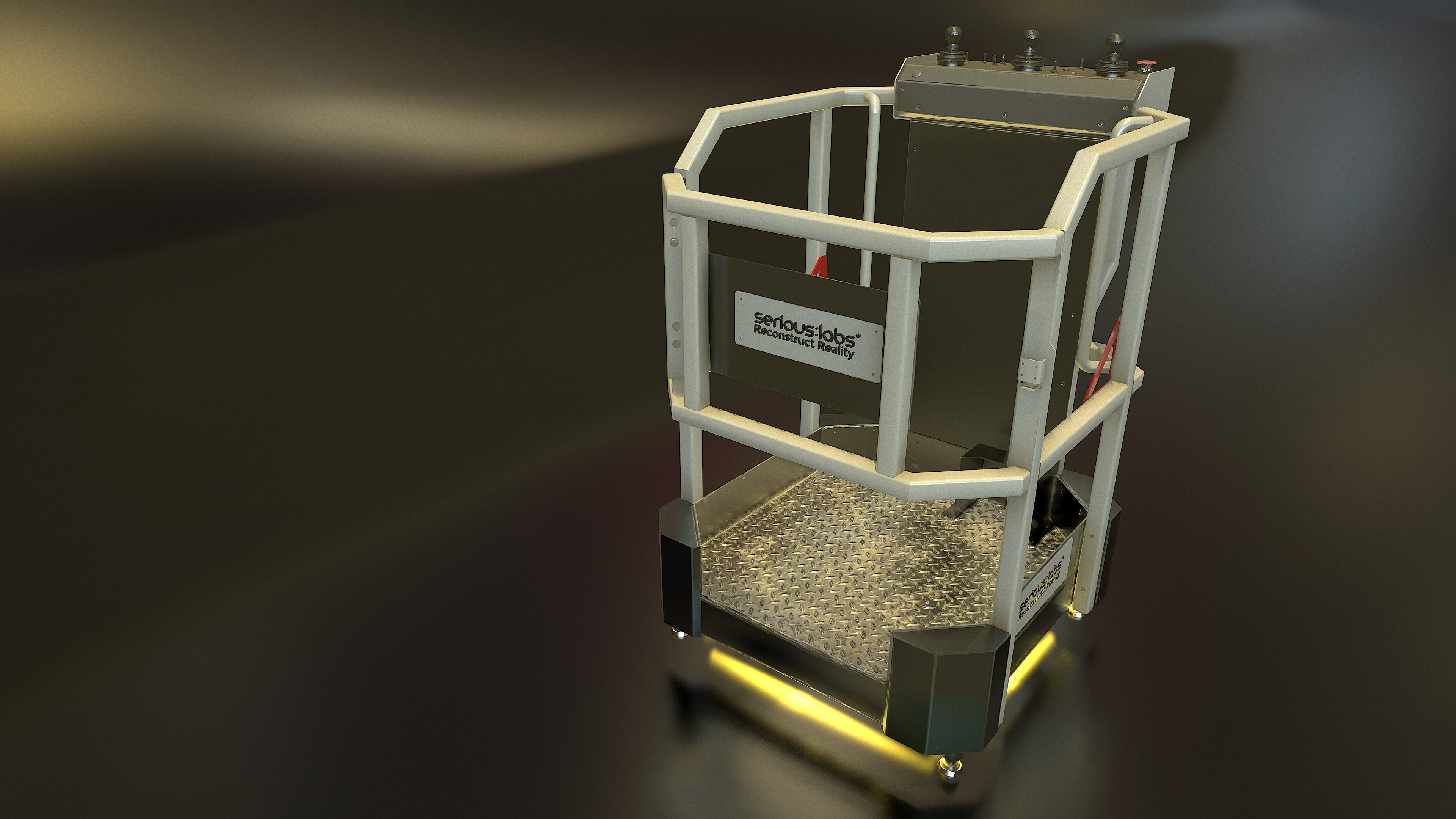

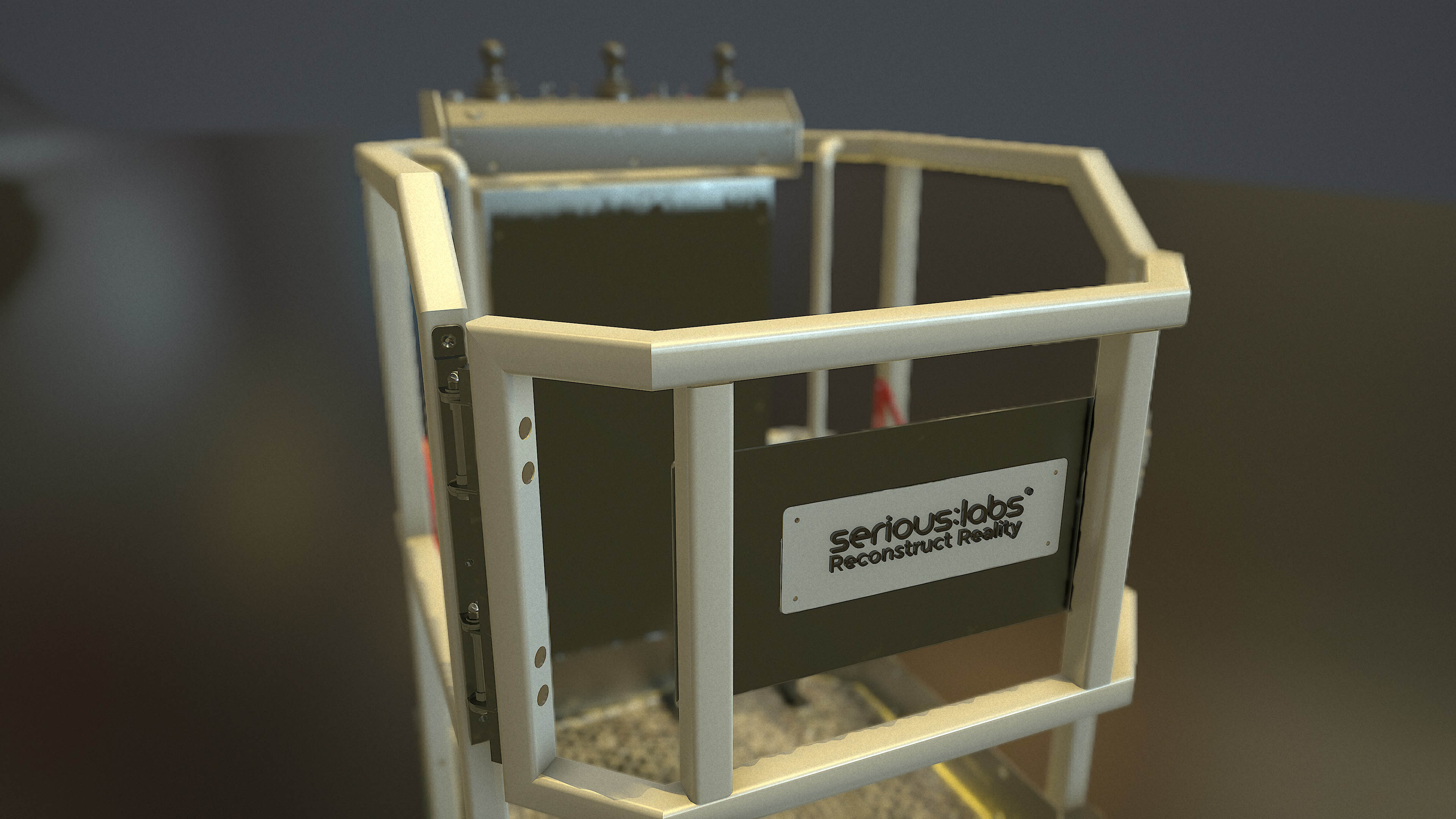

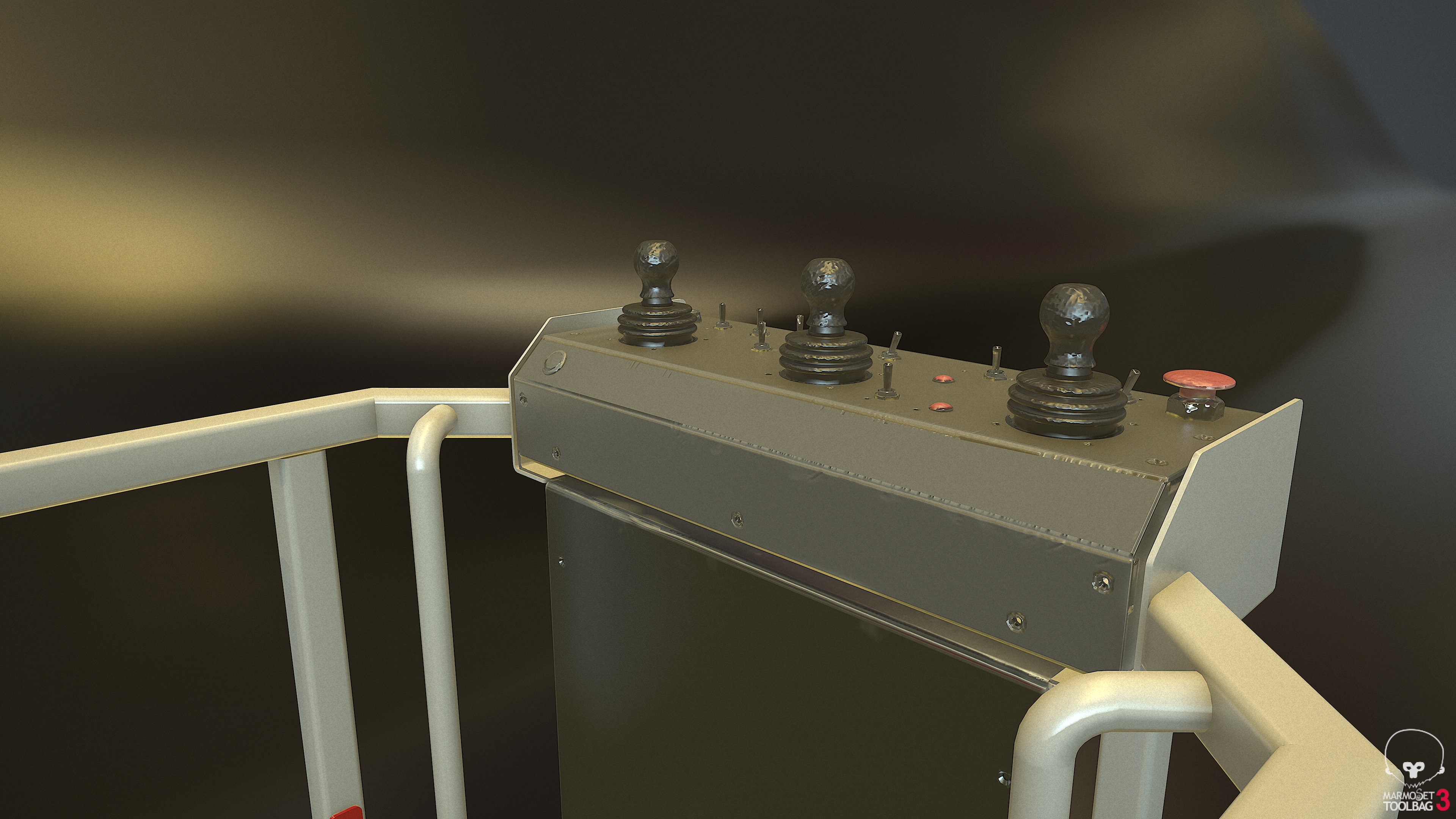

We know that practical learning is rooted in real-world experience, at Serious Labs, we use groundbreaking technology to make training safer and more engaging than ever before. Introducing the ‘ReachEX simulator’ , a training simulator for an articulated boom lift - designed to allow your trainees to work through complex environments, in the safest possible way.

Designed to be used in conjunction with conventional training as part of a blended learning approach. Using state of the art virtual reality technology, we can now replicate real life training hazards minus the physical dangers - allowing trainees to make mistakes and learn in a safe and controlled environment.

Adopted by the International Union of Painters and Allied Trades in the US as the most effective and safe method of training, our sim training covers control familiarization, basic driving, and a number of operational problem areas.

Ultimately, our Reach EX simulator brings your learners closer to the real world experience, without the hazard of a work related incident. Getting to the roots of their learning experience..